As an efficient welding auxiliary equipment, welding rotator provides welders with a stable and easy-to-operate working environment by rotating the workpiece, greatly improving the welding quality and efficiency of large or heavy parts. At the same time, Resize Machinery focuses on precise size adjustment of materials or workpieces, whether expanding or reducing the size, to ensure that the product meets strict manufacturing standards and customer needs.

Working Principle of Welding Rotator

Rotary and Turning Mechanisms

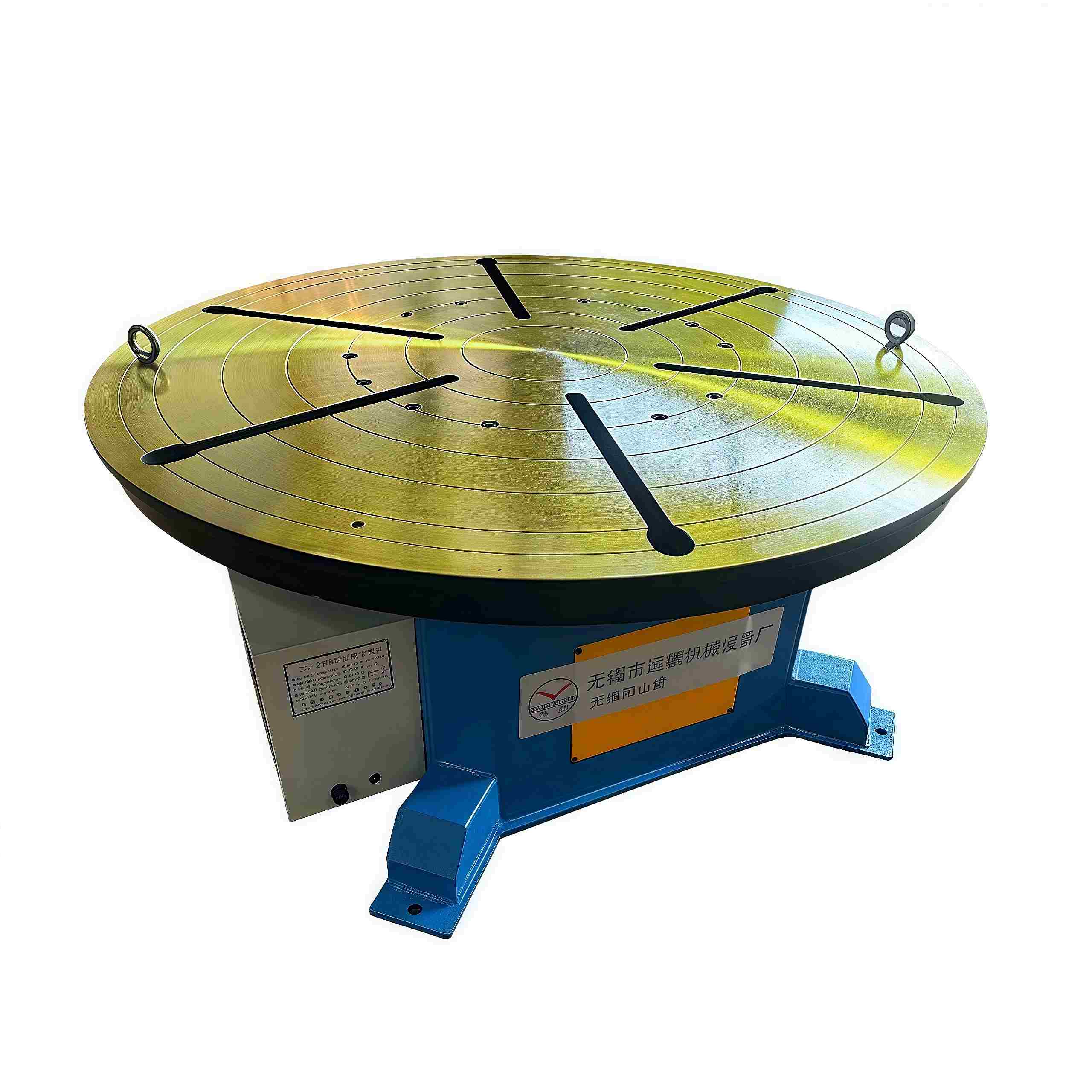

The welding positioner is primarily composed of two key mechanisms: the rotary mechanism of the workbench and the turning mechanism. The rotary mechanism enables the workbench to rotate continuously or intermittently, depending on the welding requirements. The turning mechanism, on the other hand, facilitates the lifting and tilting of the workbench to position the workpiece at the desired angle.

By combining these mechanisms, the welding rotator allows the workpiece fixed on the workbench to reach any required welding and assembly angle. This flexibility is crucial for achieving high-quality welds in complex and large-scale fabrications.

Variable Frequency Stepless Speed Regulation

One of the standout features of modern welding rotators is their ability to convert the workbench into variable frequency stepless speed regulation. This feature enables operators to adjust the welding speed precisely, ensuring optimal welding parameters are maintained throughout the process. Whether working with thin sheet metal or thick structural steel, the variable speed regulation ensures a smooth and consistent welding experience.

Applications of Welding Rotator

Welding of Large Structures

Welding rotators are indispensable in the welding of large structures such as tanks, vessels, and pressure containers. By rotating these structures, welders can access all welding seams without the need for awkward positions or complex setups. This not only improves welding efficiency but also enhances the quality of the welds.

Assembly and Fabrication

In addition to welding, welding rotators are also used in assembly and fabrication processes. They facilitate the precise alignment of components, ensuring that the final assembly meets all specifications and tolerances. This precision is particularly important in industries such as aerospace, automotive, and marine, where safety and performance are paramount.

Inspection and Testing

Welding rotators also play a crucial role in inspection and testing phases. By rotating the workpiece, inspectors can easily access all areas for thorough examination. This ensures that any defects or imperfections are detected early, allowing for prompt corrective action.

Resize Machinery: Selling Points of Welding Positioners

Advanced Rotary and Turning Mechanisms

Resize Machinery's welding positioners are equipped with state-of-the-art rotary and turning mechanisms. These mechanisms are designed for maximum durability and precision, ensuring that workpieces are positioned accurately and held securely throughout the welding process.

Variable Frequency Drive System

Our welding positioners come with a variable frequency drive system that provides stepless speed regulation. This feature allows operators to fine-tune the welding speed to match the specific requirements of the workpiece and welding process. The result is a smoother welding experience and higher-quality welds.

User-Friendly Controls

Resize Machinery understands the importance of ease of use in welding operations. Our welding positioners feature intuitive controls that make it simple for operators to adjust settings and monitor the welding process. This user-friendly design reduces the learning curve and increases overall efficiency.

Customizable Solutions

We offer a wide range of welding positioners to suit various applications and workpiece sizes. Our team of experts can work with you to design a customized solution that meets your specific needs. Whether you're welding small components or large structures, Resize Machinery has the right welding positioner for the job.

Superior Customer Support

Finally, Resize Machinery is committed to providing superior customer support. Our dedicated team is available to assist you with any questions or issues you may have, ensuring that your welding operations run smoothly.

Conclusion

Welding rotators are essential tools in the welding and fabrication industry, offering unparalleled versatility and precision in welding operations. By understanding their working principle and applications, as well as the selling points of Resize Machinery's welding positioners, you can make informed decisions that enhance your welding capabilities and improve your bottom line.

https://www.resizeglobal.com/working-principle-and-application-of-welding-rotator.html

www.resizeglobal.com

无锡市远鹏机械设备厂