Relays are essential components in various industries, serving as switches that control the flow of electrical currents. They play a crucial role in automation, telecommunications, power systems, and many other fields. In this article, we will delve into the fascinating world of relays, exploring their different types and shedding light on their diverse applications.

- Electromechanical Relays:

Electromechanical relays are the most common type, utilizing an electromagnet to control the switching mechanism. They consist of a coil, armature, and contacts. When the coil is energized, it generates a magnetic field that attracts the armature, causing the contacts to close or open. These relays are widely used in power systems, industrial automation, and control circuits due to their reliability and versatility. - Solid-State Relays (SSRs):

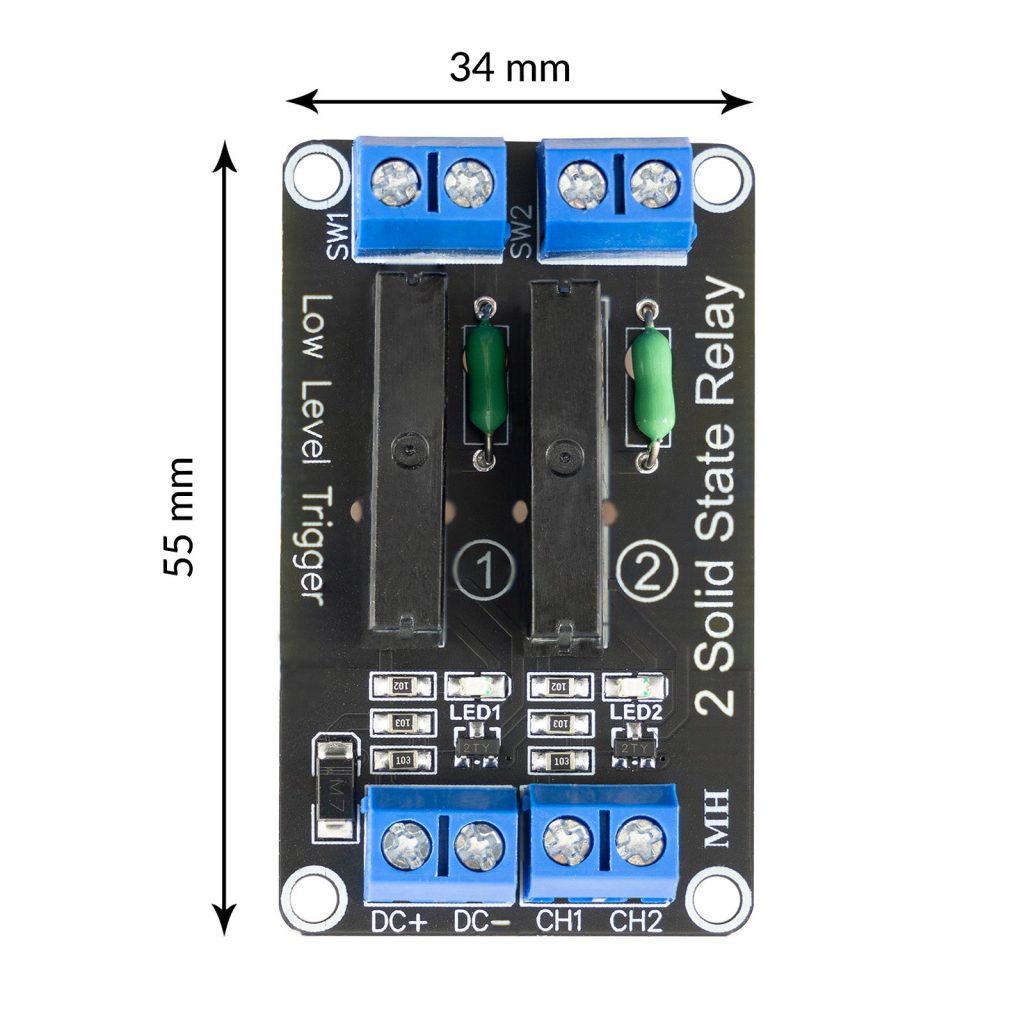

Solid-state relays have gained popularity in recent years due to their numerous advantages over electromechanical relays. Instead of using mechanical components, SSRs employ semiconductor devices, such as thyristors or transistors, to perform the switching operation. They offer faster switching speeds, higher reliability, and longer lifespan. SSRs find applications in areas where silent operation, low power consumption, and resistance to shock and vibration are critical, such as medical equipment, robotics, and automotive systems. - Reed Relays:

Reed relays are unique in their design, utilizing reed switches enclosed in a glass tube. The reed switch consists of two metal reeds that are hermetically sealed and actuated by an external magnetic field. When the magnetic field is present, the reeds come into contact, completing the circuit. Reed relays are known for their compact size, fast response time, and excellent isolation. They are commonly used in telecommunications, test and measurement equipment, and high-frequency applications. - Mercury-Wetted Relays:

Mercury-wetted relays employ a pool of liquid mercury as the switching medium. When the coil is energized, the mercury forms a bridge between the contacts, allowing the current to flow. These relays offer extremely low contact resistance, high reliability, and excellent performance in high-frequency applications. However, due to environmental concerns regarding mercury, their usage has significantly decreased in recent years. - Polarized Relays:

Polarized relays are specifically designed to operate in DC circuits. They consist of a permanent magnet that provides the polarizing force and a coil that generates the switching force. The permanent magnet ensures that the relay operates in a specific direction, preventing accidental reversal of the current. Polarized relays are commonly used in telecommunication systems, automotive applications, and battery-powered devices.

Conclusion:

Relays are indispensable components in various industries, offering precise control and protection in electrical circuits. By understanding the different types of relays, including electromechanical relays, solid-state relays, reed relays, mercury-wetted relays, and polarized relays, engineers and technicians can select the most suitable relay for their specific applications. Whether it's ensuring the reliability of power systems or enabling the automation of industrial processes, relays continue to play a vital role in advancing technology and innovation.